Clean room, also known as clean room, is a high-tech facility to control the concentration of suspended particulates in the air, widely used in semiconductor, biomedicine, food processing and other industries. To achieve a true dust-free state, comprehensive management needs to be carried out from many aspects. The following are the key measures to achieve a dust-free workshop:

Air Purification System :

High efficiency air filters must be installed inside the dust-free workshop to filter and purify the air entering the workshop to ensure that particles and microorganisms in the air are effectively removed. Air purification is the basis for a dust-free workshop to achieve a dust-free state, and the filter needs to be replaced regularly to maintain its efficiency.

Cleaning Management :

The dust-free workshop needs to be thoroughly cleaned regularly, including the floor, walls, ceiling, equipment, etc., using appropriate cleaners and tools to ensure that there is no dust and particulate matter residue. This requires the use of professional cleaning equipment and trained cleaning personnel.

Personnel Management :

Personnel entering the dust-free workshop need to be strictly managed, including dressing rooms, hand washing and disinfection procedures. Before entering the workshop, you must wear dust-proof work clothes to avoid bringing external dust into the workshop. This involves regulating the use of Clean clothing and ensuring that people do not become a source of pollution.

Environmental Monitoring :

The dust-free workshop needs to be equipped with environmental monitoring equipment to monitor the concentration of particles in the air, temperature and humidity and other parameters in real time to ensure that the environmental quality of the workshop meets the requirements. This helps to detect and resolve problems in a timely manner and to maintain a dust-free state.

Equipment Maintenance :

The equipment in the dust-free workshop needs to be regularly maintained, including cleaning, overhaul, and replacement of parts, to ensure the normal operation of the equipment and avoid dust caused by equipment faults.

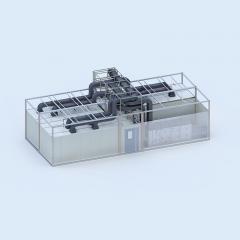

Layout Design :

The layout design of the dust-free workshop needs to consider factors such as air flow direction and equipment layout to ensure that there are no dead corners in the workshop, which is convenient for cleaning and maintenance. This involved the design of the

cleanroom ceiling system and

cleanroom wall panels, which needed to be able to support the requirements of a dust-free environment.

Special Facilities :

Clean room door: The door of a dust-free workshop needs to be well sealed and easy to clean to prevent dust from entering.

Cleanroom ceiling : The ceiling system needs to be able to support the installation of HEPA filters and be easy to clean and maintain.

Clean room windows : Windows need to be well sealed to maintain cleanliness in the workshop.

Clean Room Air shower : The air shower is used to remove dust from the surface of people and items, and is an important purification step before entering the clean room.

Through the effective implementation of the above measures, the dust-free workshop can achieve a more ideal dust-free environment to ensure product quality and production safety.

Интернет Сервис

Интернет Сервис